Beer has been brewed at the Antarctic stations for many years; sending commercially packaged beer down south takes up valuable cargo space, thus it is more efficient to send limited quantities and brew the majority on-station.

The empty commercial beer bottles are refilled with the home brew – commonly called “Homers”.

In the past, the homers was made from the basic ingredients – yeast, a starter from previous brews, malt and the usual ingredients. Nowadays, commercial home brew kits are used.

Bottling nights are a social event at the stations and many people, including non-drinkers attend.

Here are some stories about brewing beer at the stations.

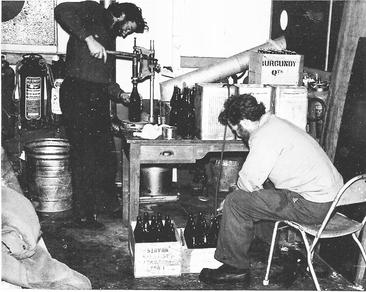

Mawson 1959

Bottling Home Brew, Biscoe Hut Mawson. Photo by Grahame Budd

I had brought the recipe from Heard Island, where in 1954 it had been known as ‘Azorella juice’. But my grateful patients at Mawson had produced the poster seen on the door, which celebrated its virtues and ended with the punch-line “Your doctor will tell you – it’s good for you!”

The figures, left to right, are ionospherics physicist Ross Dunlop and senior meteorologist Ian Widdows, who earlier in the year had had a retrocaecal appendix removed while lying on one of the mess tables and (being a tall sort of chap) the sewing machine.

Compliance, I’m happy to report, was 100%.

Grahame Budd.

Mawson 1966

I am sure the location was in Biscoe where they had a corner set aside where it could be temperature controlled for the production of the ‘perfect brew’. As I was tee-total at the time I was not personally involved but beer drinkers got a ration which from memory was two cans a week which was usually kept for Sunday dinner or for the monthly themed party’s. So Monday to Saturday it was homers as you say.

All those involved contributed, I think it was 10 shillings each to purchase enough ingredients before departure to make enough brew for the year.

Regarding a ‘fort knox’ I really hadn’t thought about it but I guess it would have been kept somewhere pretty safe, although I can’t really imagine anyone being game enough to rob the nest-egg although I do remember that the actual ‘testing’ of the brew was a very popular activity.

John Le Quiniat (Quinert)

Ron Murray & Bill Cartledge, Mawson 1966

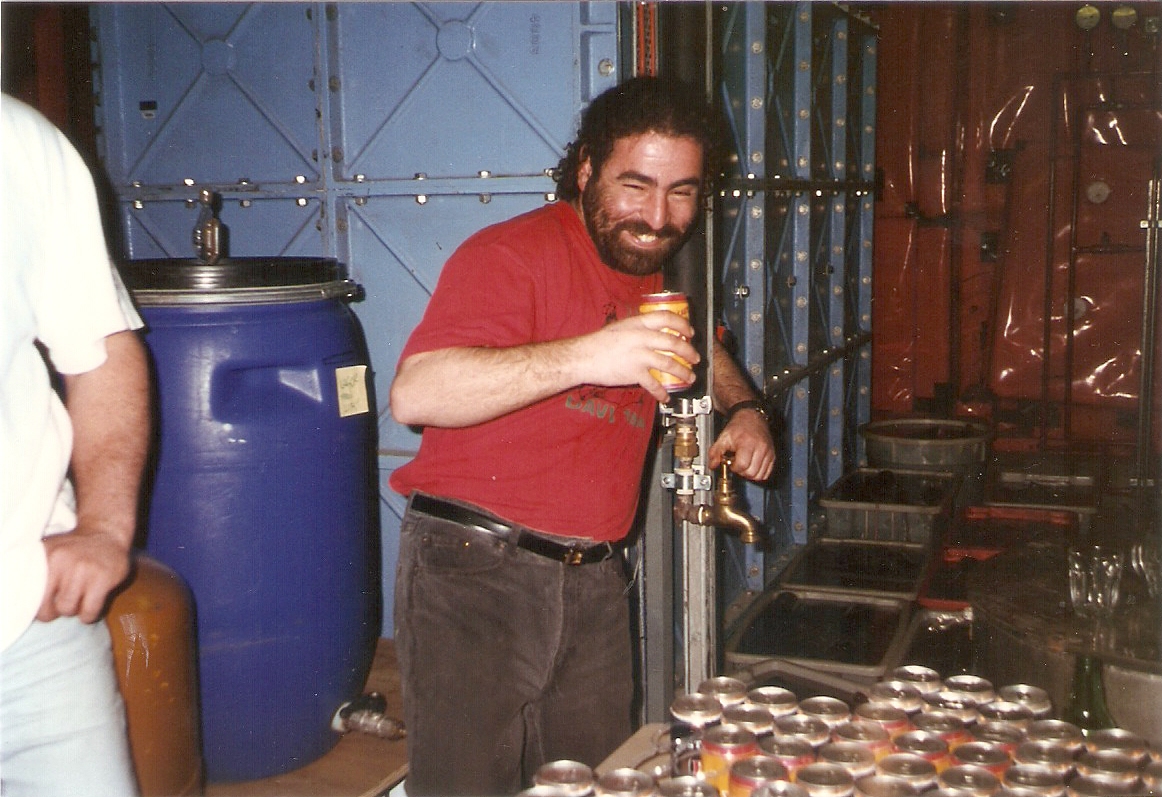

Davis 1996

As one of the time honoured traditions, being Brew Master was up there. Plenty volunteered to partake, but not as many volunteered to make.

We came into a Summer where brew was in abundance, with plenty of stockpiles to choose from. There was little need for the previous year to make some so the supplies were suitably matured (some more than others!). The labels were on the caps and the most memorable was one called “Cats Piss” The name said it all.

After the Summerers had left, we set about making some brew for us and the next Summer. We had plenty of empty bottles and plenty of stocks delivered.

We had regular gatherings in the Living quarters plant room. Even Yassa installed a “Brass Tap” specially for our use. Usually on a week night, after the day’s work, we plugged away, washing and cleaning then filling the bottles. Hard work required constant hydration during the process and at the end we could sample some of the older brews till late into the night.

Yassa and his Brass tap

Along the way there were many of stories. Knowing the amount of sugar we go through to make a brew, I noticed in the “Green Store” were huge amounts of honey. This was being sent down on a per person ration expectation and we weren’t using it.

So I asked Chef “Squeaza” if I could use it to make some Honey Lager! It was a huge success. The jars even were the glasses with handles so we could re-use them in the mess too as drinking glasses. Everyone wins.

On the occasion the Kapitan Khlebnikov arrived in harbour, full of tourists, for afternoon tea Squeaza had cooked up a great feast but many migrated to the bar to taste our home brew. It was here that one of the passengers of the ship pulled out two bottles of Home Brew they were given at Mawson, to sample against the brew found at Davis. It was an unbiased judgement, provided by the passengers only, voting unanimously, the Davis brew was the best. We then continued “sampling some more”.

The brewing area was also a good (well stocked) starting point for a pub crawl around station. One of our Summering crew “Spud” was getting married on his return to Oz and we all couldn’t attend his Bucks Party – so we had one on Station instead.

Peter Field, Brew Master 1996, Web Master 2019 –

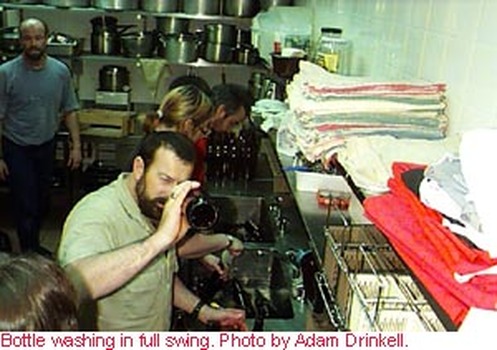

Mawson 1998

The whole ‘home brew’ bottling extravaganza runs over 2 weeks. Brooksy, Ron and Peter, our ‘brew masters’ keep an eye on the stocks and decide when to make more beer. Looking through the log books, most years bottle 3 or 4 times, capping around 400 bottles on each occasion.

We have bottled twice already this year – in February and March, to replenish stocks after summer. This was our third bottling – not so much because stocks were low (apparently we’ve drunk very little over winter) but more to have a large number in reserve for the summer onslaught and beyond. The bottles, which have been bought from Boy Scout Associations over the years and shipped down, number around 1700. Of these about 1000 are currently empty.

Everyone pitches in at one stage or another although there are a few ‘die hards’ who just love to be present at every stage of the beer making process. This includes the initial drinking of the beer, subsequent rinsing of the bottle with water and storage in the Red Shed basement.

There comes a time when Brooksy declares a ‘Great Bottle Washing’ night. All 400 are bought up to the kitchen, scrubbed and washed in a sodium metabisulphate solution. It’s a fast moving operation with the teams of washers often ‘competing’ to get the most washed. There’s a lot of rivalry, laughter and splashing. (Well perhaps not too much official splashing as water restrictions are in place and the plumbers have beady eyes.) The bottles are then drained, dried and stored in the basement under plastic to protect from dust.

Mawson Kitchen. From front to back: Kim (Kimbo) Barnsley, Ashleigh Wilson, Andrew Brooks, Michael Keam

In basement of the Red Shed, Mawson

Inspired by our enthusiasm, the brew masters then make up the beer. You probably know all this but I thought I’d outline the highly secret Mawson Home Brew Technique, codenamed MHBT.

Alternatively you could read the back of the tin can the brew kit comes in.

Generally we combine the contents of 7 cans with 7 kilograms of sugar dissolving the two in 10 litres of hot water. An additional 150 litres of cold water is then added to the ‘fermenter’, a 200 litre stainless steel drum with an air tight lid and fitted air lock. After mixing, 3 sachets of brewer’s yeast (thoughtfully provided by the company) are added, the drum sealed and the whole lot left to ferment for between 7-10 days. Fermentation is complete when there is no more gas bubbling in the air lock and the specific gravity of the mixture is less than 1.006.

Once this stage is reached the word goes out once again. The actual bottling of the beer is very relaxed. Firstly a teaspoon of sugar is added to a clean bottle which is then filled with fluid from the fermenter. The bottle is sealed with a metal cap (my favorite job) detailing the type and batch no, inverted four times (the worst job because juggling them is distinctly frowned upon by Brooksy) and stored until required.

Most of the home brew is lager, although we also make small quantities of stout, draught and black and tan (a mixture of lager and stout). This time cider was brewed as well.

The majority of the beer is consumed over summer when there is an influx of people (station numbers more than double) and there is much more of a party atmosphere at night. In addition we often get one or two cruise ships visiting during the summer season. The visitors usually wind up at the bar after a tour of the station and are shouted a few drinks.

The home brew is really used to supplement our own personal supplies of alcohol. Think how it is at home – whether you’re partying, at a BBQ, hosting a formal dinner, celebrating a birthday or enjoying a quiet time with friends – many adults would have at least one alcoholic drink and often more.

It’s no different here. In fact the only difference is we can’t just zip out to a bottle shop, pub or restaurant to buy what we want. Instead we have to purchase all our alcohol a year in advance and ship it down with the general station cargo.

Even then you can’t bring in unlimited amounts. There is a basic restriction of one cubic metre on the amount of personal luggage you are allowed to take to the station. While there is some flexibility in the amount, there’s not that much flexibility! Still the Division helps out – supplying a small amount of wine and spirits for the group – these are usually put out for Saturday night dinners. In addition we receive a carton of beer each month, although that privilege is soon to cease. These stores are kept over in ‘Fort Knox’ in the Green Store and distribution organised by Kimbo.

I think a fair proportion of the carton beer disappears at Friday ‘after work’ drinks. The drinks are a bit of a tradition here. Held most Friday nights before dinner, a different work area is responsible for hosting them each time. Several weeks ago it was Met (always a favorite as Ash and Maria always make yummy ‘finger foods’), last week it was held in the new cool room which is being constructed. This Fridays was a classic.

The Diesos are currently servicing the ‘Seeka’ in the Red Dwarf workshop, our 7 metre mono-hulled boat. They decided to host drinks in the boat… one of our more exotic locations. Lifejackets were optional for once.

Writing about alcohol on station is like stumbling through a minefield. I think as a group we have a fairly balanced attitude. Although it doesn’t dominate our social life, it’s a part of our life…

Excerpt from ‘Ingrid on Ice’ , ABC website, 22/8/1998

Fort Knox was located in the Green Store at Mawson station. If there wasn’t sufficient room at resupply to store the alcohol, boxes were placed on shelving along the right wall of the Green store.

Mawson 2002

Times change and the brewery moves with it. The Mawson brew has improved and Bruce kept it flowing.

Small kegs have been introduced and brewing in stainless steel 44 gallon drums makes things very sterile.

Casey 2010

Is anyone able to provide additional information re the beer brewing process at this time – if so please please contact webmaster@anareclub.org.au

Photo by Amy Bulters